Errore nel formato dell'e-mail

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

Notizia

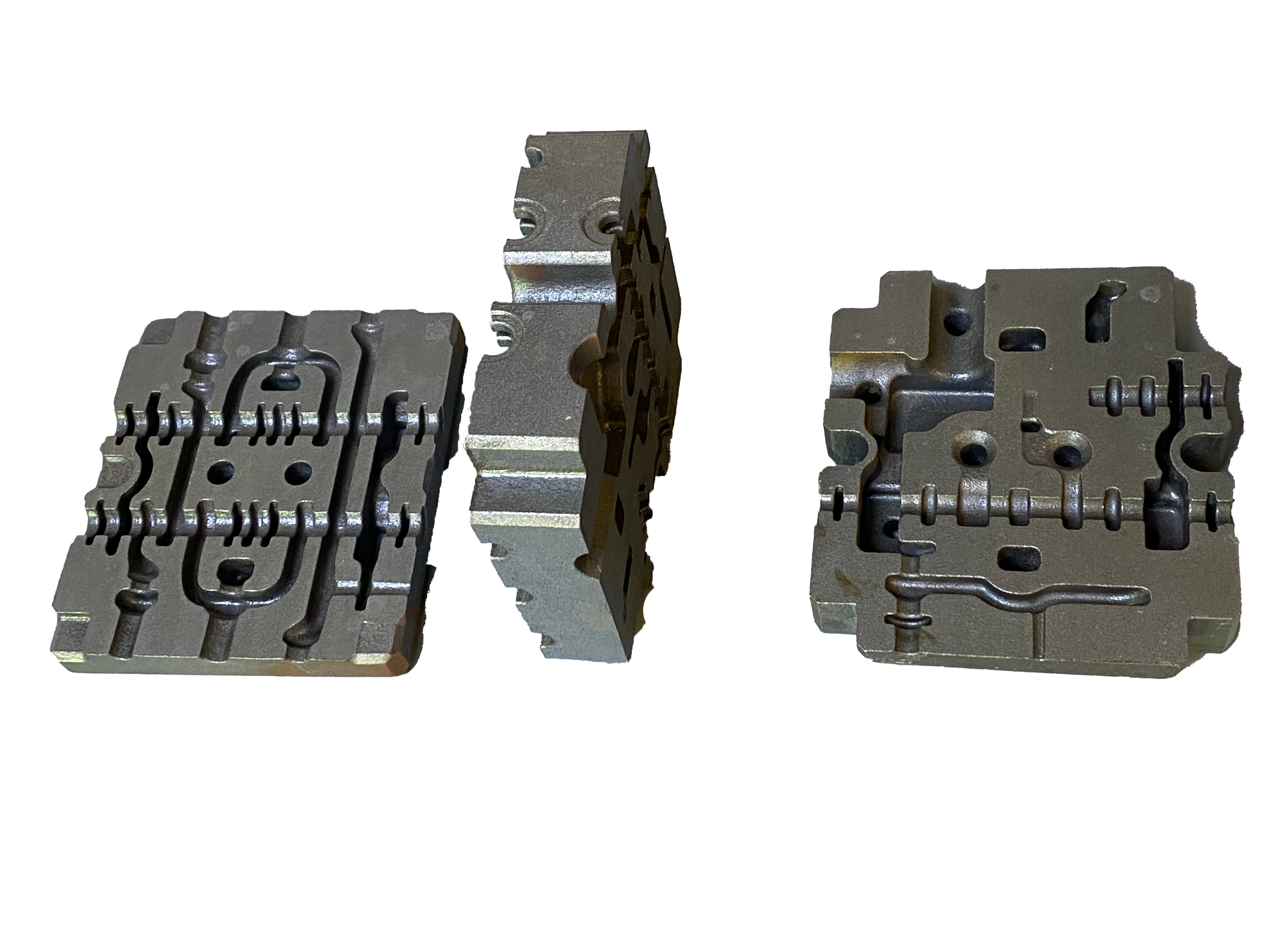

Talking about the Film in Cast Iron(1)

When the molten iron is kept at a high temperature (1500 ℃) in a furnace or a molten iron ladle lined with traditional refractory materials such as silica, you can see a charming scene. The surface of the molten iron is dotted with silent and mysterious flashing fragments from time to time. These phenomena suddenly appear and expand to a size range of several centimeters in about a second. The debris drifts circularly, merges with other debris, and finally sticks to the vessel wall, solidifies and cools on the vessel wall, and enters the slag shell. These fragments are formed by droplets melted from refractory materials on the molten iron ladle wall and ladle bottom. When the ladle is tilted to empty it, the upright "stalactite" at the bottom of the ladle and the upward protrusions and droplets on the wall of the ladle can be seen, which just marks the position of the droplet separation.

Like all components in the molten metal system, when molten slag reacts with molten metal, it will quickly change its composition. At high temperatures, iron, manganese, and silicon in the slag will be reduced from their respective oxides into molten iron, and those stable oxides, such as aluminum and calcium oxides, will converge into dry slag, or slag. The thickness of these slag layers on the surface of molten iron can reach more than 0.1mm (in a cupola, this thickness is usually greater than 100mm).

Heine and Loper of Wisconsin University have done a lot of work since 1951 to explain the formation of complex films in cast iron. Later, Merz and Marincek's work also further elaborated on this. Based on these works, we can explain the various changes that occur when the temperature drops.

When Fe is at a high temperature of 1550 ℃, CO is a more stable compound than SiO2. Therefore, carbon will be preferentially oxidized and lost at a higher rate than Si. Si begins to decrease only after all C is exhausted. Under such high temperature, there will be no film on the surface of the liquid metal, and any silicon oxide such as SiO2 will be immediately reduced to silicon metal in the liquid metal, dissolved in the liquid, and at the same time, co will be generated and discharged into the atmosphere.

At about 1420 ℃, the stability of carbon and silicon oxides is reversed. The exact temperature of the transition depends on the composition of Fe. Below about 1400 ℃, SiO2 appears on the surface as a dry solid gray film. This layer of film cannot be removed by wiping the surface, because it will constantly regenerate.

At 1300 ℃, MnO is the most unstable, SiO2 is the second, and CO is the most stable. Therefore, Mn is oxidized first, then Si, and finally C. The contribution of MnO at this stage may be to reduce the melting point of the film and turn it into a liquid.

At about 1200 ℃, the oxide FeO of Fe further reduces the melting point of the ternary eutectic phase of FeO, MnO, and SiO2. If s exists in molten iron, MNS will reduce the melting point of the complex eutectic phase to 1066 ℃.

Searching for a cast iron products, reconditioning cast iron skillets, smith and clark cast iron manufacturer from China, you can get high-quality products at a nice price.